CNC Tool Grinding

Cutting Tool Engineers continuously invests in the latest tool manufacturing technology.

Cutting Tool Engineers has a highly trained team that operate our CNC (computer numerical control) machines. Together, these individuals have over 75 years of experience with five-axis tool grinders. The machines are calibrated to perform consistent and precise tool grinding. Each machine is connected to a filtration system that filters the grinding oil, and maintains the temperature level throughout the work day. This enables the machines to hold critical tool tolerances through extended grinding periods.

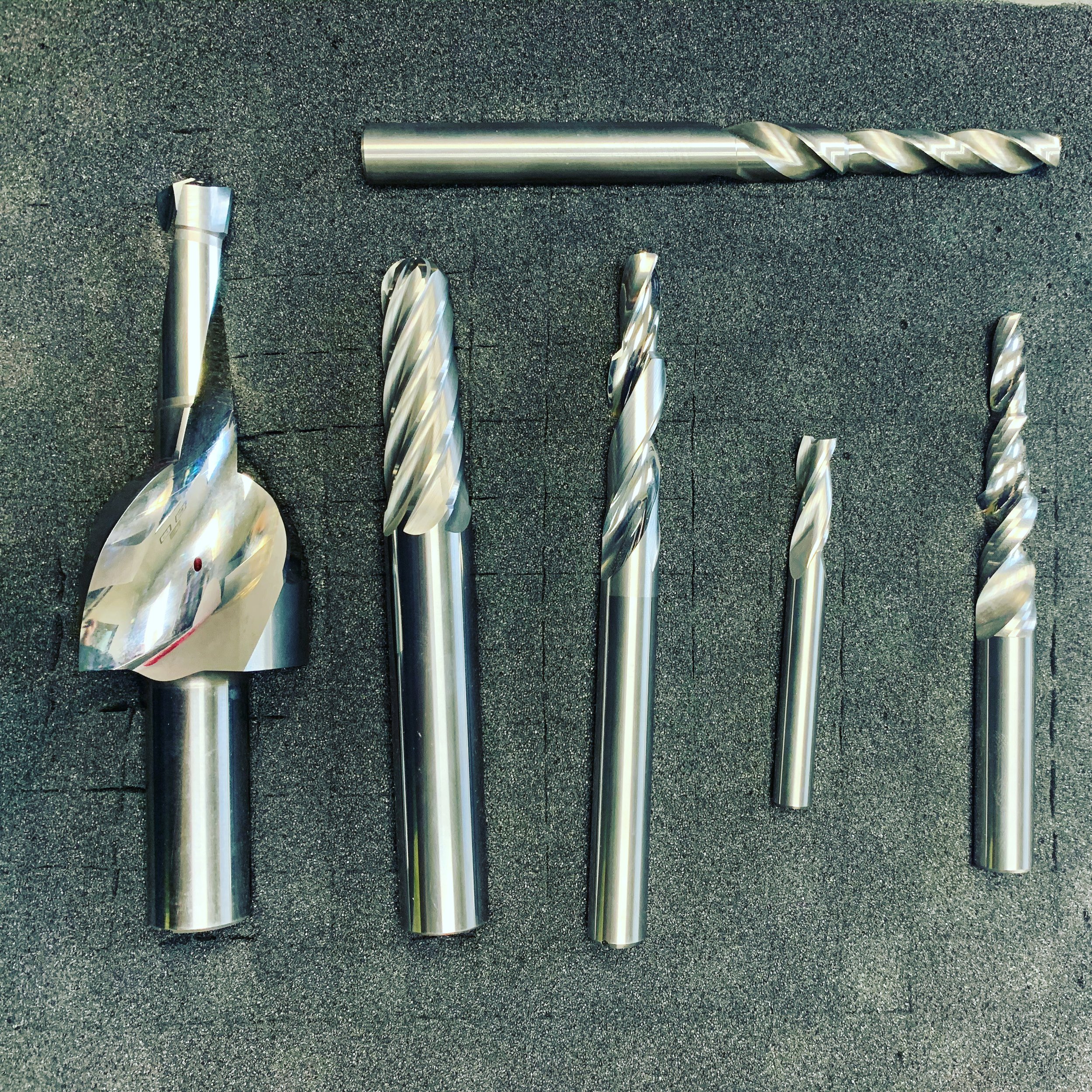

The CNC capabilities have enabled us to manufacture special tools to consolidate our customers’ machining processes. Our goal is to provide our customer with the ability to reduce their machining time with durable special tools. Whether sharpening high performance carbide end mills, or manufacturing high speed steel form tools, Cutting Tool Engineers is dedicated to producing the best possible tool to fit your needs.

The tools include:

Drills

End Mills

Tapered Tools

Porting Tools

Dovetail Tools

Step Tools

Step Drills

Form Tools

Tapered Reamers